영문 주메뉴

- COMPANY

- BUSINESS

- CAPABILITY

- PRODUCT

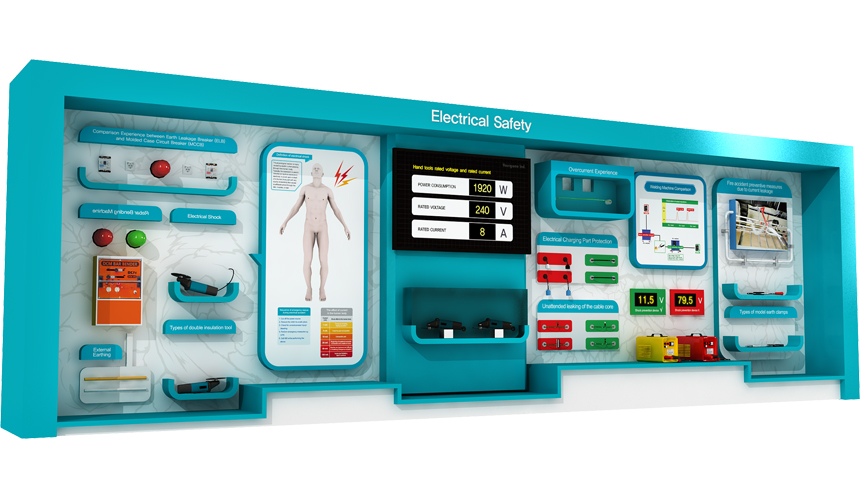

- Industrial Safety

- Construction Safety

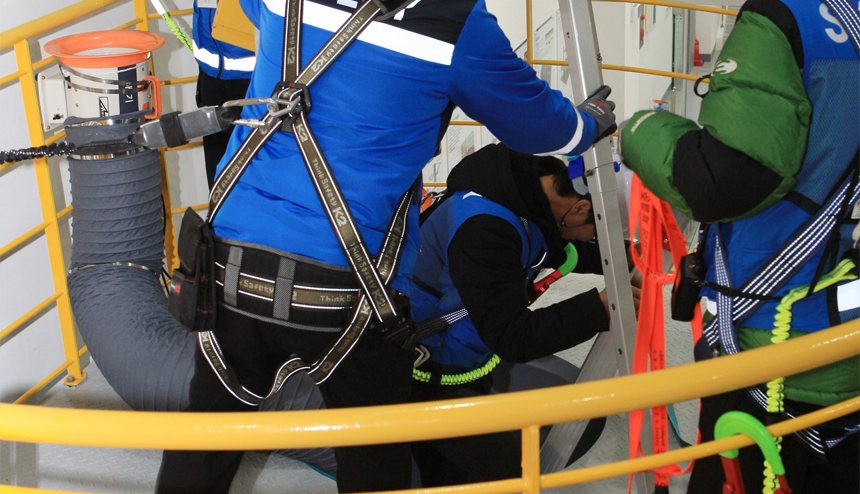

- Safety Harness and Fall

- Floor Opening Safety

- Guardrail/Scaffold Collapse

- Safety Helmet/Boots Impact

- Tunnel Safety

- Steel Structure Safety

- Mobile Platform

- Temporary Passage

- Vertical Ladder

- A-Frame Ladder Collapse

- Poor Passage

- Rooftop Sliding

- Aerial Work

- Descending Life Line

- Gondola

- Gang Form Fall

- Scaffold Safety

- Retention Wall Collapse

- Falling Objects

- Manual Handling

- PPE

- Machinery Safety

- Civil Safety

- VR Safety

- Movable Type

- CONSTRUCTION PERFORMANCES

- CUSTOMER